This is the fourteenth entry in a nineteen part series that covers the construction of one of my saws from start to finish. For links to the other entries, please see the full chronological index. -Ed.

For another method of closing the slot, please see this later post. The method described therein requires less specialized equipment. -Ed.

Stamping & closing the slot

To stamp the back, I use a maker’s stamp from Infinity Stamps. This one cost nearly $200 several years ago, but was worth every penny. The quality is exquisite, and their service was outstanding.

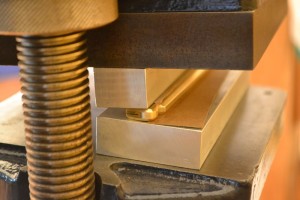

The stamp can be either struck or pressed. For consistency, I use a hydraulic press and a jig to hold the back and the stamp.

Several sharp-eyed readers have noticed that the following pictures are not of the back we have been following in previous posts. That back called in sick on the day we were shooting, so this one was used as a stand-in. -Ed.

There are many ways to attach the back to the blade. Others who build with slotted spines use Loc-Tite, epoxy, screws, or rivets; my blades and backs are held together by friction. To create this friction, I spring the slot by squeezing the back in my hydraulic press. With the proper application of force, the width of the slot will be reduced by a few thousandths of an inch at the edge. It does not sound like much, but it is enough to grip the blade with enough force that separating the two is a non-trivial matter.

Hi Isaac!

Have You tried closing the slot for the blade with a mallet?

Regards,

Lukasz.

Lukasz, yes that will work. I’m going to try to get some pictures or video up of a couple of different ways of doing this. I just need to find a bit of time to do it.

Isaac

Pingback: Closing the slot; An addendum to saw build along – Back, Part III | Blackburn Tools

Pingback: Saw build along index | Blackburn Tools

Pingback: I will never see a saw the same again - Stoner Creek